Green

Wood is an extraordinary material. A resource that is capable of renewing itself naturally. Wood is light, it is resistant, it emanates warmth and a particular feeling of welcome. Wood is flexible, guarantees high performance, is excellent for acoustic insulation and above all lasts over time: this is why it has always been one of the most important building materials. The use of wood also represents a very simple way to reduce carbon dioxide emissions, the main cause of climate change. Elegant in its naturalness, wood is the raw material used for the production of Itlas floors. Over thirty years of history and experience that have become passion and love for their products and for the wood they are made of.

Wood plays a fundamental role in the battle to curb climate change. Forests help to reduce the amount of carbon dioxide present in the atmosphere and the use of wood-based products therefore stores CO₂. Wood products store CO₂ initially incorporated in trees, extending the period during which carbon dioxide is kept out of the atmosphere. Increasing the use of wood is a simple way to reduce emissions that cause climate change.

Wood is a renewable and versatile raw material that can be reused, recycled or used as an energy source at the end of its first cycle. It is important to remember that the production of wooden floors generates very little waste: the residues, chips and sawdust - produced during processing - are used to produce thermal energy. Wood energy is CO₂ neutral. Using wood processing waste and wood waste as an energy source is the final link in the virtuous cycle of wood. Wood provides an alternative energy to fossil fuels that can be used instead of being wasted in landfills. Since it only releases back into the atmosphere the CO₂ that was extracted from the atmosphere by growing trees, wood combustion does not contribute to global warming or the greenhouse effect.

The raw material used by Itlas for the production of wooden floors comes from sustainably managed forests certified PEFC or FSC®. The selection is made directly by the company, which takes part in the most important timber auctions. The majority of the floors marketed by Itlas are made of oak wood, which comes from certified French forests and from Serbia. Since 2009, the company has also been using Italian beech wood from the Cansiglio Forest, which is PEFC certified.

The paper used by Itlas is FSC® certified, confirming its environmental philosophy. The FSC® international certification system guarantees that strict environmental, social and economic standards have been met in the production of a wood or paper product.

ITLAS packaging is increasingly green-oriented. In addition to cardboard boxes (recyclable), the company has started using 100% recycled shrink wrap and 30% recycled bubble wrap. With the aim of using lighter packaging, the company has started using a thinner but more technical and therefore more performing stretch film.

All the lamps for lighting the production plants and the warehouse were replaced with LED lamps in 2020, which reduce energy consumption by 40% compared to neon lights.

Plastic bottles are out. ITLAS, in line with its environmental sustainability path, has decided to eliminate bottled water for internal consumption since 2020.

We purchase ECOPALLET® certified pallets, made from PEFC certified wood and produced using renewable energy.

We purchase certified green electricity with the aim of saving 1,300 tons of CO₂ per year and taking a further step towards carbon neutrality.

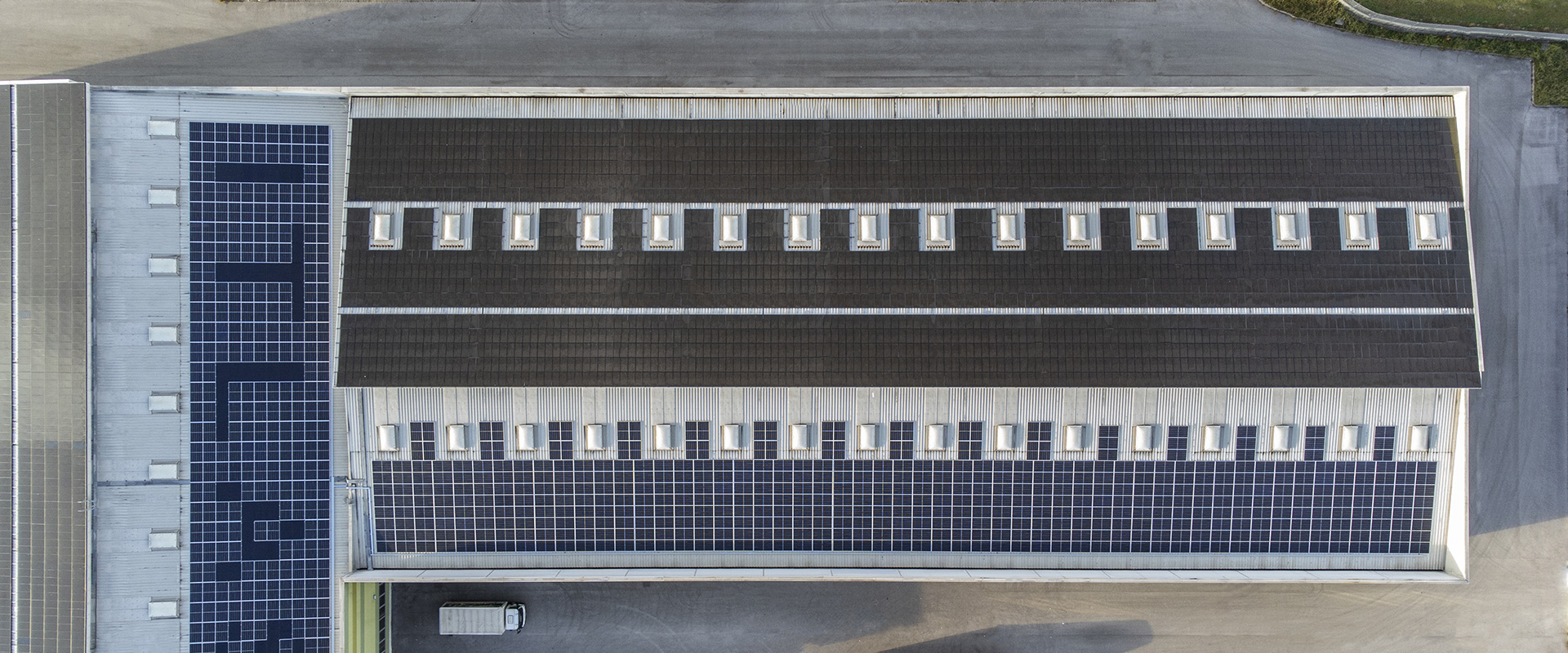

In 2011, the company took a significant step forward in the field of clean energy by embracing photovoltaics: 4,172 panels covering the 3,304.22 square meters of the roof of the new production plant. Three generators, four inverters, for a grid-connected system, an annual capacity of 372.570 kW and an annual energy production of 370,755.66 kWh. A choice that last year allowed the company to reduce CO₂ equivalent emissions by about 45% and ozone-depleting substances by over 55%, while also avoiding the continued consumption of non-renewable resources.

Fill out the form adding your request and we will contact you as soon as possible.